By Veriquality Inspection Service Co.,Ltd Source: Veriquality Inspection Service Co.,Ltd

What are the Key Elements of Factory Audit?

Factory audit refers to an onsite factory inspection that is carried out on behalf of an importer at the premises of the manufacturer before placing an order to a new manufacturer. Factory Audit is aimed at avoiding getting involved in a bind working with the wrong factory. Factory audit is not the same as Auditing based on quality management systems not only concerning about quality management system also including background, industrial experience and exporting history.

When you looking for a new factory to work with, it is the key step for your successful business.With pressures from poor rice production on the rise and labor throughout China unstable,more China-based manufacturers are closing shop every day. It is better to discover these early and manage them proactively rather than being surprised when a critical issue arises.

But what are key elements for the factory audit especially when you want to source product from a new supplier and factory?

1. Verify Supplier Legitimacy

Working with your supplier comes with risk

especially for new suppliers, but a factory audit from a reputable quality

control firm minimizes uncertainties. Initially, it is key to collect all the

necessary certification and license to be able to sell and export goods. In

China, the business license will include the information related to which date

to be registered and scope for operation. If the manufacturer without

production wording in business license then means the factory is illegible for

production. Also, need to collect the renting contract or property ownership

certificate to verify if the building is legitimate for production.

2. Verify Production Process?

Why is production process key for new factory audit? The production process included much information related to the expertise and capability for the production. For the small organization, it is very common they only have one production process of an assembly line or combined several simple production processes. If the factory only has simple production process, it means the factory is hard to control most aspects of quality by themselves. More production process was subcontracted to other suppliers will increase the risk of quality issue.

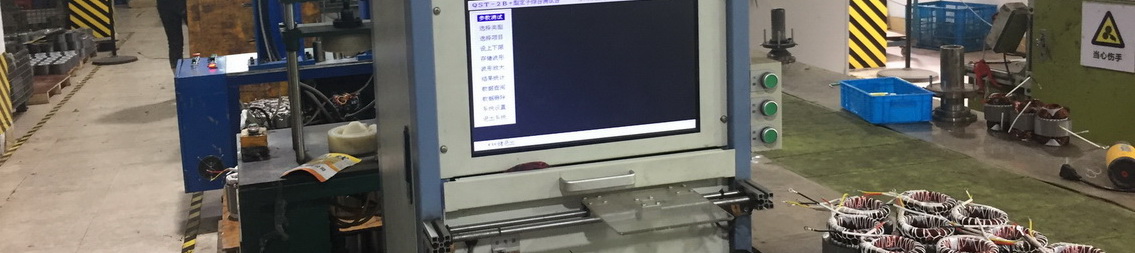

3. Machinery and Equipment, measuring tools

To collect the information for machinery and

equipment will help you to judge if production capability and production

process control can meet your expectation. I have one client they want to

purchase children rainboot from different suppliers. One supplier with own mold

making workshop and Italian injection machine and another supplier without mold

making workshop and domestic injection machine. Initially, the client looking

for the partnership with the factory who did not have mold making workshop due

to they have the cheaper price. During the production, the factory can not

control product quality due to permanent defects of the outsole for shrinkage.

The factory showed they did not have the capability to design mold properly and

reliable injection machine. Finally, the client ends the relationship with this

factory.

4. Verify human

resource

Verify human resource also is key for the factory

audit. When you get the clear information of human resource structure, you can

judge if how many workers for production, how many people for product

designing. If the factory only has production department and without the

quality assurance department, it means that the factory will lack necessary

control for product quality. If the product development and engineering dept

available, then means they have engineering capability will help a lot of

production.

5. Verify

production capability

The most data showed in the audit report of production capability is not accurate. Why? Considering the time of the audit, the auditor only asked the manufacturer to provide the data and record it. How to get accurate data? I think if the manufacturer can provide annual production report then the data is more accurate. If without this kind of annual production report, we can ask the manufacturer to provide an annual contract of one big client.

6. Verify the quality management system

The auditor

will measure the effectiveness of the factory’s Quality Management

Systems (QMS). They’ll evaluate them based on the ISO

9001 standard. And you’ll come out with a much clearer

picture of whether or not there are any quality risks to your supply chain.